+971559524625

Machines and Spare parts Design

A Real Success

Designing machines and Modifying Spare-parts to match the customer's requirements and market needs, redesigning parts of machines to improve the performance and last longer than ever.

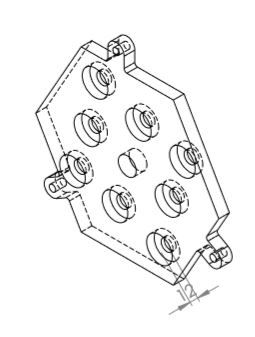

In Backside photo Jaw plate for Jaw crusher i have designed, now released in some countries by the manufacturer

Silo Dust Collector

Featured Showcase

|  |  |

|---|---|---|

|  |

Check out my Silo Dust Collector Project which Maximizing dust filtration efficiency with new technology attached with steel structure which designed and Implemented in Oryx Industries L.L.C - Oryx Crushers L.L.C., Particle filters are an essential component in any powder storage silo, providing safe ventilation of air without expelling product into the atmosphere.

The storage of powdered product in silos is commonplace in a wide range of processes in diverse industries. However, there are important safety considerations associated with the operation of storage silos, particularly during the filling process when excess pressure can become trapped within the silo.

The importance of Silo Storage after air classification system is must, which maximize the safety and health measures for the workers and environment, and reduce the handling process used by equipment which will save time and diesel consumption

Introducing WP20-150 Aggregates Washing Plant

A Lifetime of Creations

Over the years, I’ve had the opportunity to work on a number of incredible projects that have allowed me to grow and establish myself within this competitive industry in which Sand from a washing screen becomes a solution with water and is fed into the bucket tank of the washer. Most of the coarse sand is taken away by the buckets, drained, and discharged. . The course of this sand sinks to the bottom and is removed to the buckets for discharge. The water flow rate is an important factor, as a material with a high percentage of fines to be removed, will require a high volume of water. with more water recycling phases.

Bucket-wheel dewaters also boast a big decantation basin, providing great flexibility in control of feeding amount with feeding frequency control. An option for slow operating speed means a very low wear part cost, even for abrasive materials, as a low speed causes less friction and creates better results for fine material recovery. These features make the bucket wheel dewater one of the most cost-friendly solutions for washing applications.

The results may vary depending on feed material gradation, density, clay content, amount of water used, equipment settings, and washing application

Don't hesitate to contact for ordering one.

|  |  |

|---|

Freelancing

A better way

Only a short note about some items i have designed before, more designs will not allowed in the show for classified matters

New Addition

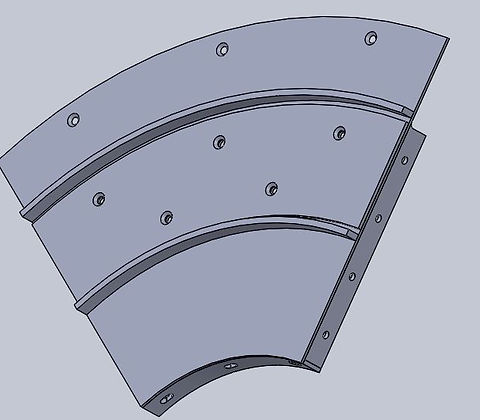

Air Classifier

The wearing rate of wearable liners inside the machine is too high and costly, gently i have changed the used material and redesign the liner to fit to our feeding material hardness and modify the thickness and material used in the liners that leads to cheaper answerable liners with efficient and higher life time

New Challenge

Blow Bars

A freelancing project for Omani customers to modify there blow-bars and redesign, the new blow bars are more efficient by filling the spaces that materials always stuck and make perfect alignment with old machine to meet its dimensions.

Top Seller

Impact Liner

The new design of impact liner using higher rate of manganese alloy, and wit smother design, allow the part to last longer, this part have released by the manufacturer in some countries and its giving a good feedback.